1-888-728-9481

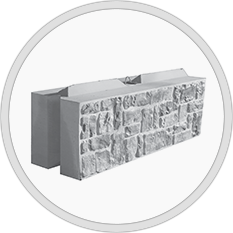

V-Interlock

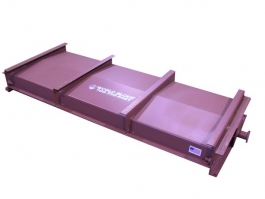

Down and dirty, the V-Interlock Block is not meant to be pretty, it’s meant to get the job done. At 2 feet high, 2 feet wide and 6 feet long, the block form takes 24 cubic feet of concrete to make a 3,600 pound block. If you need to get rid of a cubic yard of concrete, this form will do the trick.

The granddaddy of all block forms, the V-Interlock block form has been used for years in the industry as the go-to form for straight-forward, get-it-done-now applications. These blocks are perfect (and most commonly used) for industrial applications such as batch plant fencing and product divider bins.

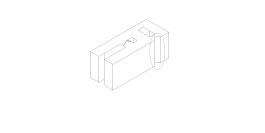

A raised “male” V notch runs along the top and down one side of the block while an inner “female” V notch runs along the bottom and up the other side. V-Interlock blocks are the only blocks to interlock on all four sides.

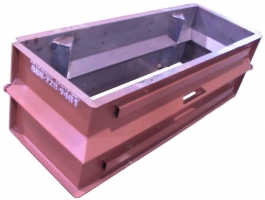

Built as two “L” shaped halves your forms lock together at the corners using two heavy-duty, over-center locking clamps. This design allows for easy set up and stripping. The clamps can be used as levers to help you pop the form open after the block has cured.

A convenient liftpoint blockout is already welded in place. Our lifting loops make the easiest and most affordable lift point. Simply slide one end of the cable loop into the slot of the blockout and you are ready to pour. Some customers have found it helpful to stuff a rag behind the liftpoint or cover the slot with duct tape to prevent concrete from oozing out. The reinforced sidewalls make your forms rigid enough to handle the biggest load.

The forms are poured with the face down. The sides of the form make the top, bottom and sides of the block. After stripping, just grab the liftpoint and tip the block upright. Getting rid of concrete has never been easier.